Switched Reluctance Motor (SRM) Development

The Centre for System Design (CSD) at NITK Surathkal is actively engaged in the research and development of Switched Reluctance Motors (SRMs) as a sustainable and cost-effective alternative to traditional BLDC motors for electric vehicles (EVs). This project aims to address the high costs associated with permanent magnet (PM)-based motors by developing innovative SRM solutions that are robust, fault-tolerant, and magnet-free.

Featured Images

Explore our collection of stunning images showcasing our products and services.

SRM Design and Prototyping

Inner Rotor Standard SRM (2 kW)

Designed for E-Rickshaw applications, this motor leverages rugged and reliable SRM technology to enhance the durability and performance of small commercial EVs.

Outer Rotor Hub Motor (0.5 kW)

Targeted for E-bicycles, this lightweight and compact hub motor offers efficient and cost-effective mobility solutions.

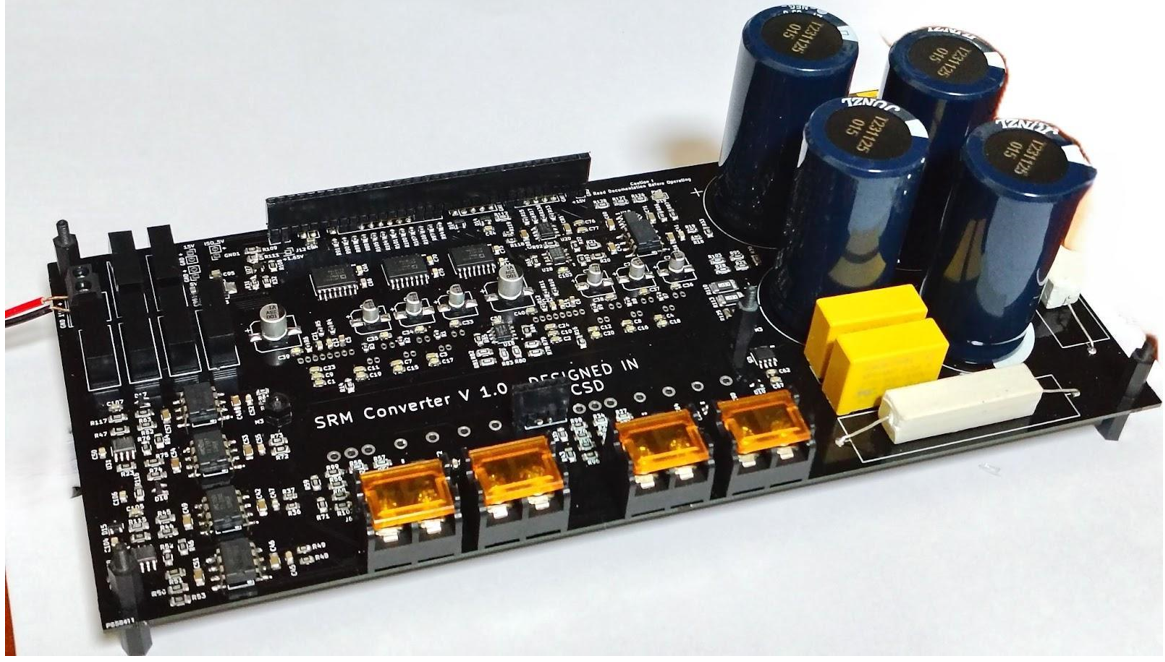

SRM Controller Design

CSD has developed controllers capable of driving motors up to 600V and 40A. These controllers are designed in-house to be modular and cost-effective, utilizing industrial IGBT modules and novel configurations to meet the needs of four-phase motors.

- Modular and cost-effective design

- Industrial IGBT modules

- Adaptable to different motor requirements

- Expertise in MCUs, DSPs (STM, TI), and FPGA-based solutions

Control Algorithms and Sensor Integration

Control Algorithms

- Hysteresis Current Control

- Voltage PWM

- Soft and Hard Chopping Algorithms

- FPGA controllers for precision and versatility

- MCUs and DSPs from STM and Texas Instruments

Sensor Integration

The team has experimented with diverse rotor position sensors (hall effect, IR, magnetic rotary) and integrated current sensors to refine motor control and enhance performance.

Key Features:

- Multiple sensor types supported

- Enhanced motor control precision

- Improved overall performance

SRM Testing Facilities

Eddy Current Dynamometer

For motor loading

Torque Sensors and Encoders

For accurate torque and speed measurements

Oscilloscopes and Thermal Imagers

For comprehensive performance analysis

SRM Project Details

.jpg%3Fheight%3D300%26width%3D400&w=828&q=75)

Project Overview

Our SRM (Switched Reluctance Motor) project aims to develop an alternative to BLDC motors for Electric Vehicles, supporting the 'Atmanirbhar Bharat' initiative. We're focusing on applications for 2-Wheeler and 3-Wheeler EVs, utilizing advanced software and partnering with industry leaders.

Project Cost: ₹16.98 Crores

Funding Agency: Ministry of Heavy Industries

Industrial Partner: Aditya Auto Pvt Ltd., Bangalore

Software Used: Electromagnetic Finite Element Analysis, MATLAB, and CAD

Project Status: Completed

Outcome: Two prototype SRMs (for E-Rickshaw and E-Cycle) fabricated and tested, with a controller developed

Future Scope: Implementation of SRM technology at the vehicle level, paving the way for more efficient and cost-effective electric vehicles in India.